TESTIMONIALS

Previous

Next

Previous

Next

TESTIMONIALS

Previous

Next

Previous

Next

Broadoak Energy

Rig Patterson UDI 118, County Reagen, Wolfberry Play,

Multi well operation infill and extension drilling.

Multi well operation infill and extension drilling.

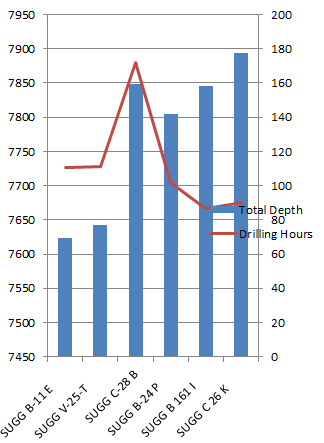

| No | Well Name | Comments |

|---|---|---|

| #1 | SUGG B-11 E | Bit Rotating hours 110.5, one bit run, Total footage 7624′ Spud to TD 6 days (apparently this was unusual, a “snow well” the bit just dropped down with no problems but came out very worn). |

| #2 | SUGG V-25-T | Bit Rotating hours Total 111 hours, two Bit runs. Total footage 7642′ Spud to TD 7 days |

| #3 | SUGG C-28 B | Bit Rotating hours Total 172 hours, two bit runs, Total Footage 7848′ Spud to TD 13 days The Corsidick sands impacted bit performance. |

Average Bit Rotating Hours for three wells prior to running Auto-Dril Navigator was 131.6 hours per well, Average well 8.67 days

| We installed the NAVIGATOR and the next three wells were as follows; |

|---|

| #4 | SUGG B-24 P | Bit Rotating hours 102 hours, one bit run, Total footage 7804′ Spud to TD 7 days |

|---|---|---|

| #5 | SUGG B 161 I | Bit Rotating hours 86.5 hours, one bit run, Total Footage 7846′ Spud to TD 7 days |

| #6 | SUGG C 26 K | Bit Rotating hours, 90 hours, one bit run, Total footage 7894′, Spud to TD 5 days. |

The average Bit Rotating hours with Navigator 92.8 hours, the average well length Spud to TD 6.33 days