Electronic Performance Driller

The innovative Electronic Automatic Driller is the most versatile automatic Driller in the industry with numerous features that handle all types of drilling thereby ensuring optimal penetration rates whilst protecting surface and downhole equipment and offering an improved bit life

Navigator System

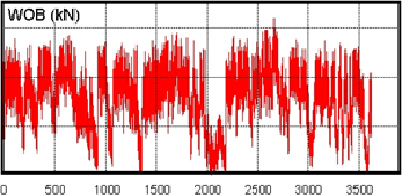

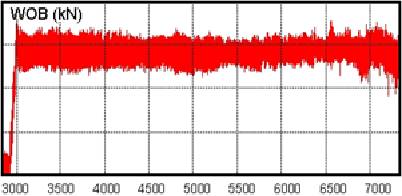

The Navigator offers machine consistent control of the drilling operation through with different custom drilling modes in addition to (WOB) weight on bit to cover any type of drilling scenario. The system significantly reduces human error, whilst delivering a steady environment a the drill bit as (measured and plotted below). This in turn produces smoother in gauge hole, improved bit and BHA life from reduced stick slip and bit whirl.

Features

Automatic system overrides for unforeseen events Weight on Bit drilling Weight and maximum pump pressure drilling Differential pressure with maximum weight on bit Rate of Penetration Drilling Time Drilling Compact rugged design, Simple to use Easy set-up and calibrate, Multiple drilling modes Low maintenance,

Benefits

Improved margin on incentive-based contracts Enhanced Safety Improved penetration rates Extended Bit/BHA life, Improved Core quality and recovery Time Drill Feature for Side Track Operations.

OUR PRODUCT

Manual Drilling

Auto-Dril

Contact Us

Delivers Improved penetration rates and savings of at least 10% in drilling time. Fast Sampling of drilling

parameters Offers a virtually instantaneous response to optimise penetration rates.

parameters Offers a virtually instantaneous response to optimise penetration rates.

Address

Phone

Navigator

Automated Drilling

TESTIMONIALS

Previous

Next

Previous

Next