SMART NAVIGATOR

Automatic Driller

Equipment Specification Sheet

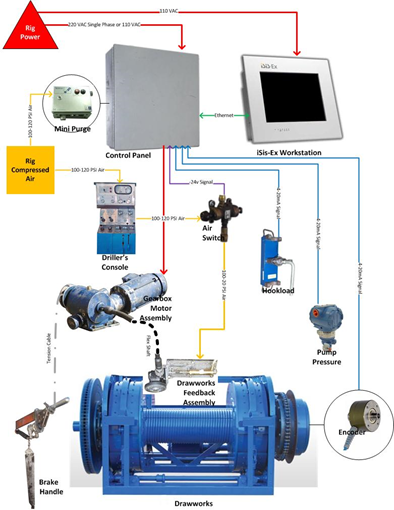

System Control Panel and Electronics

HMI – Touch Screen Controller has a 12” touch screen monitor housed in a 16”x 5” x 15.75” box to 2014/34/EU (ATEX 114). And EMC Directive 2004/108/EC. Execution II 2 G EExd IIB+H2 T5.

Control System

- Control Electronics are housed in a 16.9”x 5.9” x 13” ATEX II enclosure. (box can be mounted anywhere on the Drill Floor)

- Variable Frequency Drive controls the manual brake via the motor and gearbox.

- Gearbox and Motor (Class 1 Zone 1 rated 2 Amp motor, a single high speed clutch gearbox)

Sensors

- Hook Load - Transducers Supplied 0 to 10,000 psi. Zone 1 (Hydraulic option also is also available)

- Rotary Encoder – Optical rotary encoder 250:1 ratio for ROP and Time Drilling

- Stand Pipe Pressure Transducer – 0 – 1,000, 0 – 1, 500 and 0 -10,000 psi transducers available

- Draw Works feedback – Drum rotation sensor to allow gearbox and VFD to adjust drilling parameters.

Power – 110 / 220 volt input

Air Supply – 100 to 120 psi required

Response Time – System samples at 30 milli seconds

Air Supply – 100 to 120 psi required

Response Time – System samples at 30 milli seconds

Safety Features

- Manual emergency release on the Drillers Brake

- WOB set point -automatically stops drilling on sudden changes to parameters or WOB threshold over-run

- Pressure Differential Set Pont automatically stops drilling on pressure threshold over run.

Modes of Control

- WOB

- Differential Pressure

- ROP

- Time Drilling

Navigator Performance Verification

Data recorded on the Maxwell Downhole Technology , I Sub**

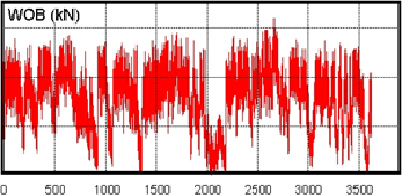

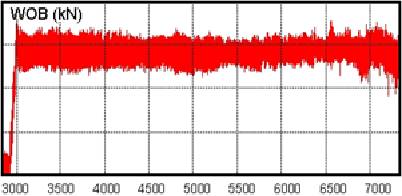

Manual Drilling

Auto-Dril

In this example, the Auto-Dril allowed the driller to:

- Inject 15‐20 % more energy into the BHA while drilling

- Minimize the risks of triggering vibrations

- Help preserve motor life (less torque variations)

SMART DRILL Navigator Summary

- The most versatile automatic driller in the industry.

- Record footage days, associated record bit runs

- Reduced drilling costs

- Extended BHA life

- Reduced down hole motor and MWD failures .

- Track record of reducing drilling time by at least 10%.

- Drilling optimization through multiple control options.

WOB Mode

- High Pressure Alarm

- Driller Percentage

- Differential Pressure Mode

- ROP Mode

- Time Drilling Mode